We are delighted to introduce KV SMART SYSTEMS, a company founded and led by technically qualified women entrepreneurs with over 8 years of experience in the fields of Industrial Automation, Instrumentation, and Design.

Read More

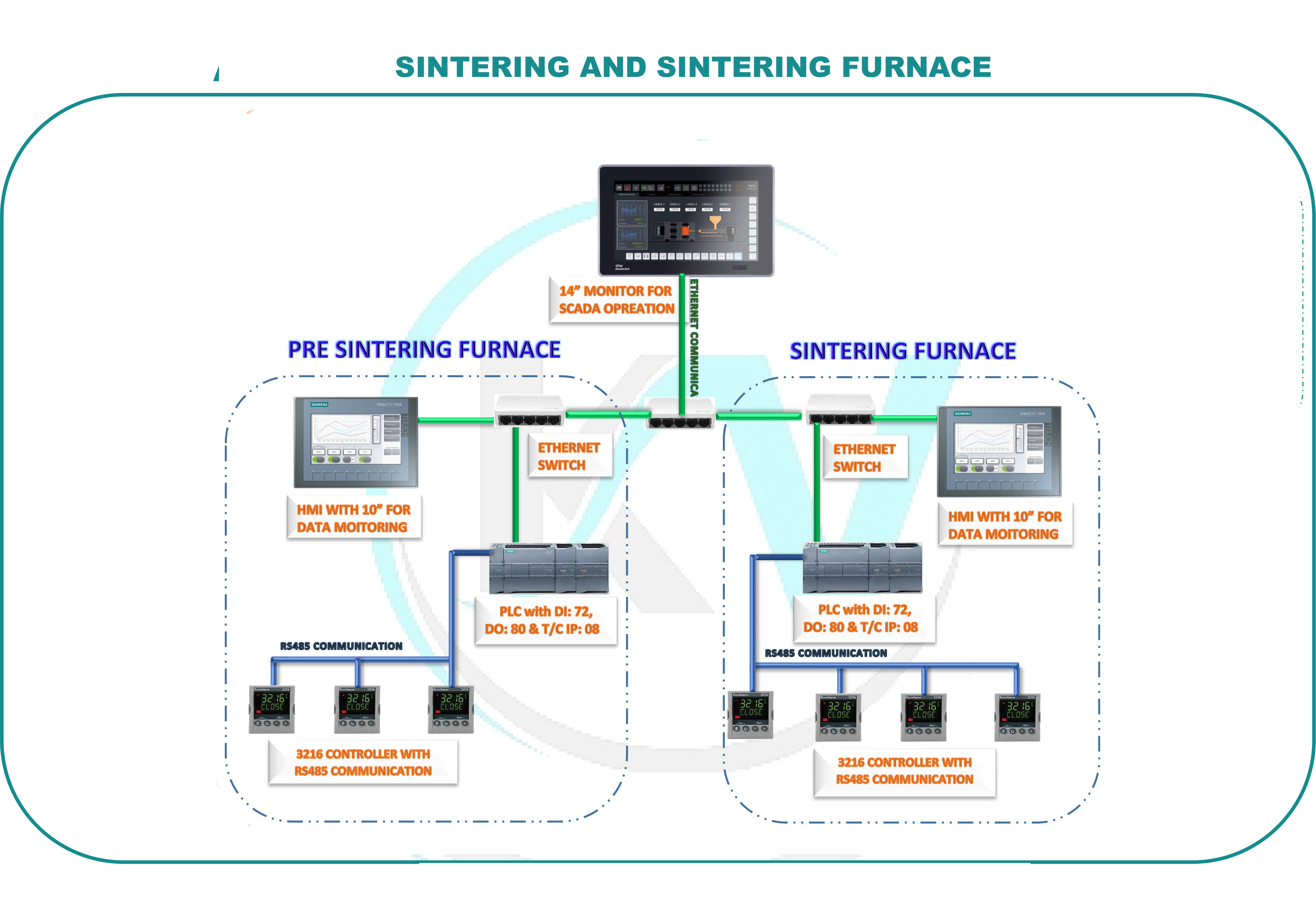

SINTERING AND PRE SINTERING FURNACE

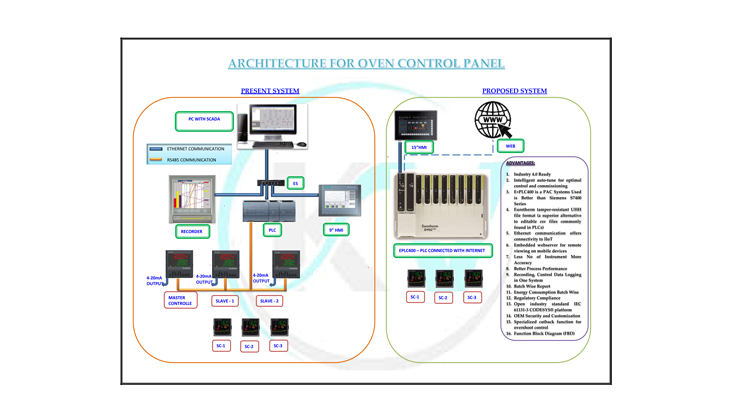

Integrating data from different systems into a SCADA (Supervisory Control and Data Acquisition) system using PLCs and Ethernet switches involves setting up a robust infrastructure for data collection, communication, and visualization.

Here’s a detailed approach on how to gather data from various systems into a centralized SCADA system:

Components Involved

- PLCs act as the primary controllers for different processes and equipment within the industrial environment.

- They collect data from sensors, control actuators, and execute control logic based on programmed instructions.

1. PLCs (Programmable Logic Controllers):

- Ethernet switches create a local area network (LAN) infrastructure within the industrial facility.

- They facilitate communication between PLCs, HMIs (Human-Machine Interfaces), SCADA servers, and other devices.

2. Ethernet Switches:

- The SCADA system serves as the central platform for data acquisition, monitoring, and control.

- It collects real-time data from PLCs and other devices, visualizes processes through graphical interfaces, and facilitates operator control and decision-making.

3. SCADA System:

Steps for Data Gathering in SCADA Using PLCs and Ethernet Switches

- Ethernet Network Setup:

- Use PLC programming software (e.g., Siemens TIA Portal for Siemens PLCs) to develop control logic.

- Configure PLCs to read data from sensors and control actuators based on predefined algorithms and logic.

1. Network Design and Configuration

- PLC Programming:

- Use PLC programming software (e.g., Siemens TIA Portal for Siemens PLCs) to develop control logic.

- Configure PLCs to read data from sensors and control actuators based on predefined algorithms and logic.

2. PLC Configuration and Programming

- Data Tagging and Mapping:

- Tag PLC variables to organize and identify data points such as sensor readings, equipment status, and control setpoints.

- Map PLC tags to corresponding data points in the SCADA system for seamless integration.

3. Data Acquisition from PLCs

- Configure communication protocols (e.g., Modbus TCP/IP, OPC UA) between PLCs and the SCADA system.

- Install necessary drivers or communication modules on the SCADA server to establish connectivity with PLCs.

- SCADA HMI Development:

- Develop graphical displays (HMI screens) in the SCADA system to visualize real-time data from PLCs.

- Design intuitive interfaces that allow operators to monitor process parameters, view alarms, and interact with control elements.

- Alarm Configuration:

- Set up alarm notifications in the SCADA system based on predefined thresholds and operational conditions.

- Configure escalation procedures for critical alarms to ensure timely responses from operators.

- Data Logging:

- Configure the SCADA system to log historical data from PLCs at regular intervals.

- Store data in a centralized database for trend analysis, performance monitoring, and regulatory compliance reporting.

- Real-Time Monitoring: Enables operators to monitor industrial processes in real-time through intuitive SCADA interfaces.

- Centralized Control: Facilitates centralized control and management of diverse systems and equipment within the facility.

- Fault Detection and Diagnostics: Supports proactive maintenance by identifying faults and anomalies promptly through alarms and data analysis.

- Scalability: Allows for scalability and expansion of the system by adding more PLCs and devices as operational needs grow.

- Integrating PLCs and Ethernet switches with a SCADA system provides a powerful solution for centralized data gathering, monitoring, and control in industrial applications. By following best practices in network design, PLC programming, SCADA integration, and data management, organizations can achieve enhanced operational efficiency, improved decision-making capabilities, and compliance with industry standards and regulations.

4. Integration with SCADA System

SCADA Communication Setup:

5. Real-Time Data Visualization and Control

6. Alarming and Reporting

7. Historical Data Logging and Analysis

Advantages of Using PLCs and Ethernet Switches with SCADA

Conclusion

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility