We are delighted to introduce KV SMART SYSTEMS, a company founded and led by technically qualified women entrepreneurs with over 8 years of experience in the fields of Industrial Automation, Instrumentation, and Design.

Read More

REMOTE IOS

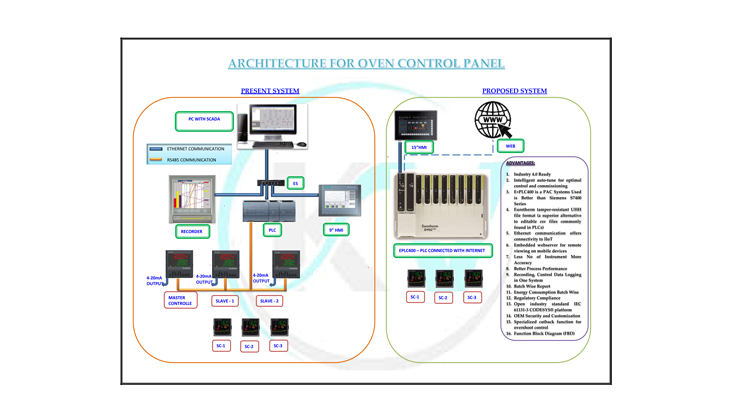

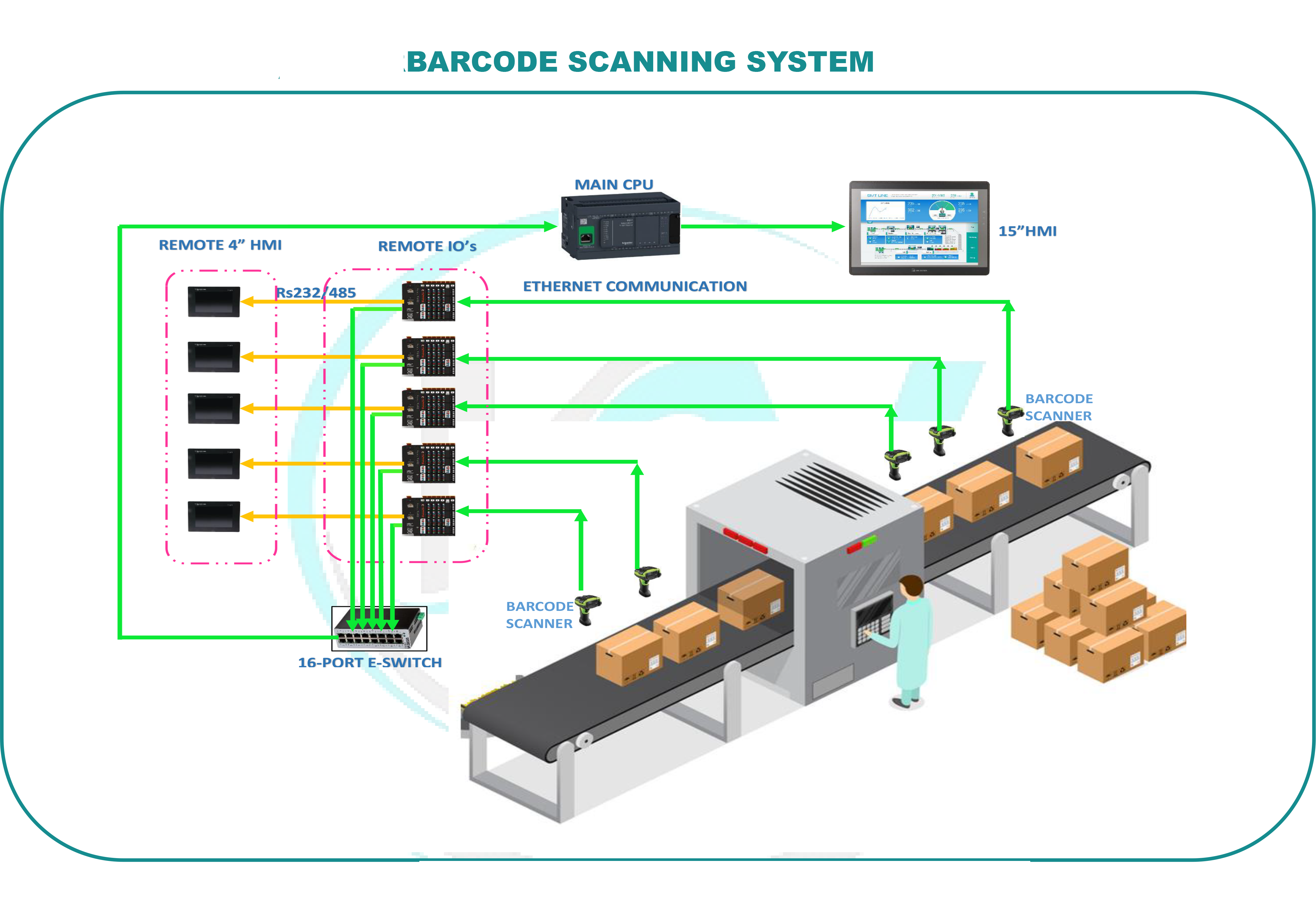

Monitoring and controlling a barcode scanner via a main PLC (Programmable Logic Controller) with remote I/O stations and HMI (Human-Machine Interface) involves integrating these components effectively to ensure seamless operation and data handling.

Here’s a structured approach to implement this system:

Components Involved

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Central controller responsible for managing the overall operation of the system.

- Executes control logic, communicates with remote I/O stations, and interfaces with the HMI.

1. Main PLC :

- Distributed input/output modules located at various points in the system.

- Interface with field devices such as sensors and actuators, including the barcode scanner.

2.Remote I/O Stations :

- Device used for scanning and reading barcodes on items or products.

- Provides data to the main PLC for further processing and control actions.

3.Barcode Scanner :

- User interface that allows operators to monitor the system status and interact with it.

- Displays real-time data, alarms, and allows for manual control and configuration.

4.HMI (Human-Machine Interface) :

Implementation Steps.

- Select PLC Model: Choose a PLC suitable for your application, such as Siemens S7-1200 or Allen-Bradley CompactLogix, capable of handling communication protocols and interfacing with remote I/O stations.

- Programming: Develop PLC logic using programming software (e.g., TIA Portal for Siemens PLCs or RSLogix for Allen-Bradley PLCs).

- Communication Setup: Configure communication protocols (e.g., Ethernet/IP, Modbus TCP) between the main PLC and remote I/O stations to exchange data reliably.

1. PLC Configuration and Programming :

- Install Remote I/O Modules: Install remote I/O modules at strategic locations where sensors and the barcode scanner are located.

- Wiring and Connection: Connect sensors, actuators, and the barcode scanner to the remote I/O modules using appropriate cabling.

- PLC Communication: Establish communication links between the main PLC and remote I/O stations to exchange data seamlessly.

2. Remote I/O Stations Integration :

- Interface Configuration: Connect the barcode scanner to the remote I/O station or directly to the main PLC, depending on the communication capabilities and requirements.

- Data Handling: Program the PLC to receive barcode data from the scanner, interpret it, and use it for further processing or control actions.

- Error Handling:Implement error-checking routines in PLC logic to manage cases where barcode scanning fails or produces invalid data.

3. Barcode Scanner Integration :

- Design HMI Screens: Develop HMI screens using software such as WinCC (for Siemens) or FactoryTalk View (for Allen-Bradley) to display system status, barcode data, and operational parameters.

- Data Visualization: Configure HMI to display real-time information from the PLC, including barcode scans, system alarms, and status indicators.

- Operator Controls:Provide controls on the HMI interface for operators to initiate actions based on barcode data, such as triggering processes or retrieving information.

4. HMI Configuration :

- System Integration Testing: Conduct thorough testing of the entire system to ensure proper communication, data accuracy, and functionality.

- Simulation: Simulate barcode scanning scenarios to validate PLC logic and HMI responses under different conditions.

- Operator Training:Train operators on using the HMI interface effectively and responding to system alerts and notifications.

5. Testing and Commissioning :

- Centralized Control: The main PLC acts as a central controller, streamlining communication and coordination between components.

- Real-Time Monitoring: HMI provides operators with real-time data visualization and control over the barcode scanning process.

- Scalability:Easily expand the system by adding more remote I/O stations and barcode scanners as needed

- Fault Diagnosis:Quickly diagnose and address issues related to barcode scanning or system operation through integrated diagnostics.

6. Advantages of the System :

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility