We are delighted to introduce KV SMART SYSTEMS, a company founded and led by technically qualified women entrepreneurs with over 8 years of experience in the fields of Industrial Automation, Instrumentation, and Design.

Read More

CHAMBER

Automated chambers are used across various industries for precise environmental control and testing. These chambers can simulate different conditions such as temperature, humidity, pressure, and light, and are essential for testing the durability, performance, and quality of products under controlled conditions.

Here are some applications and examples of automated chambers.

1.Environmental Test Chambers

Temperature and Humidity Chambers: Automate control of temperature and humidity for testing the effects on materials and products. Used in automotive, electronics, and materials testing.

- Thermal Shock Chambers: Automatically cycle between extreme temperatures to test the thermal resilience of products, crucial for electronics and aerospace components.

- Salt Spray Chambers: Simulate corrosive environments to test the corrosion resistance of coatings and materials, commonly used in the automotive and marine industries.

- Vacuum Chambers: Used in space and aerospace industries to simulate high-altitude conditions and vacuum environments. Automated systems control pressure levels and monitor the integrity of components under vacuum.

- Pressure Chambers: Test the structural integrity of products under various pressure conditions. Widely used in the oil and gas industry for pipeline and component testing.

2.Vacuum and Pressure Chambers.

- Pharmaceutical Stability Chambers: Automate the control of temperature, humidity, and light to test the shelf life and stability of pharmaceutical products. Essential for regulatory compliance and quality assurance.

- Food Stability Chambers: Test the shelf life and quality of food products under different storage conditions. Automation ensures consistent and repeatable test conditions.

3.Stability Chambers.

- Incubators: Control temperature, humidity, and CO2 levels for the growth of cell cultures and microbiological studies. Automation ensures precise environmental conditions.

- Plant Growth Chambers: Automate light, temperature, and humidity control to simulate different growing conditions for plant research.

4.Climate Chambers.

- Vision Systems: Cameras and sensors inspect molded parts for defects such as wall thickness variations, surface imperfections, and dimensional accuracy.

- Leak Testing Machines: Automated systems test bottles and containers for leaks, ensuring product integrity.

5.Biological and Medical Chambers.

- Curing and Drying Chambers: Automate temperature and airflow control for the curing and drying of coatings, adhesives, and composite materials.

- Annealing and Heat-Treatment Chambers: Control temperature profiles for the heat treatment of metals and alloys to improve material properties.

6.Industrial Process Chambers

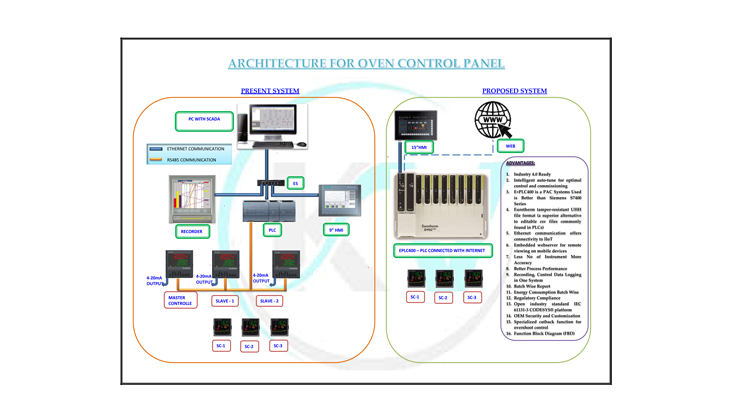

- 1.Programmable Logic Controllers (PLCs): Automate control of environmental parameters, ensuring precise and consistent conditions.

- 2.Human-Machine Interfaces (HMIs): Provide user-friendly interfaces for programming and monitoring chamber conditions.

- 3.Data Logging and Reporting: Automated systems record environmental conditions and test data for analysis and quality control.

- 4.Remote Monitoring and Control: Allow users to monitor and adjust chamber conditions remotely via connected devices.

- 5.Automated Safety Systems: Include alarms, emergency shutoffs, and fail-safes to ensure safe operation.

Automation Features in Chambers

Example of an Automated Environmental Test Chamber Process.

- 1.Setup: The test parameters (temperature, humidity, pressure) are programmed into the PLC via the HMI.

- 2.Loading: The test specimens or products are placed inside the chamber.

- 3.Conditioning: The chamber automatically adjusts to the specified environmental conditions.

- 4.Monitoring: Sensors within the chamber continuously monitor the conditions and adjust the controls to maintain the set parameters.

- 5.Data Collection: The system logs all environmental data and test results for further analysis.

- 6.Completion: Once the test is complete, the chamber conditions return to a safe state, and the specimens are removed.

- 7.Reporting: Automated reporting tools compile the test data into comprehensive reports for review.

Benefits of Automation in Chambers.

- 1.Precision and Consistency: Automated systems provide highly accurate and repeatable control of environmental conditions.

- 2.Increased Efficiency: Reduce the need for manual intervention, saving time and reducing labor costs.

- 3.Enhanced Safety: Automation reduces human exposure to potentially hazardous conditions and ensures safe operation.

- 4.Data Accuracy: Automated data logging ensures accurate and comprehensive records for analysis and compliance.

- 5.Flexibility: Easily program and switch between different test protocols, accommodating a wide range of testing requirements.

Automated chambers are crucial for rigorous and reliable testing across various industries, providing the precision and control necessary for high-quality results.

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility