We are delighted to introduce KV SMART SYSTEMS, a company founded and led by technically qualified women entrepreneurs with over 8 years of experience in the fields of Industrial Automation, Instrumentation, and Design.

Read More

Industrial furnaces

Automation in industrial furnaces refers to the integration of advanced technologies and control systems to streamline and optimize the operation of heating devices used in industrial processes.

Here are key aspects and benefits of automation in industrial furnaces:

1.Control Systems :

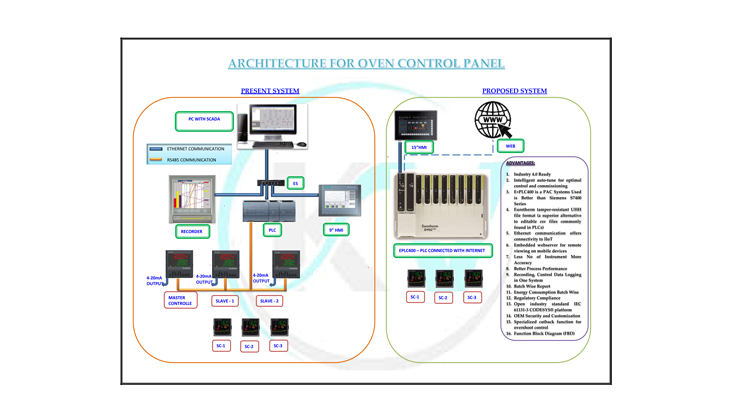

Automated control systems manage and regulate furnace parameters such as temperature, pressure, atmosphere composition, and heating rates. These systems can adjust settings dynamically based on real-time data to ensure precise and consistent heating conditions.

- Automation allows for the optimization of furnace processes to improve energy efficiency, reduce cycle times, and enhance product quality. Algorithms and predictive models can analyze data to optimize heating profiles and minimize heat loss.

2. Process Optimization :

- Automation enables remote monitoring and control of furnace operations. Operators can oversee and adjust furnace settings from a centralized control room or even remotely using connected devices. This capability enhances flexibility and responsiveness in managing production processes.

3. Remote Monitoring & Control :

- Automation systems collect and analyze data from sensors within the furnace, providing insights into performance metrics such as temperature profiles, heating patterns, energy consumption, and maintenance needs. This data-driven approach facilitates proactive maintenance and troubleshooting.

4. Data Acquisition & Analysis :

- Automation systems collect and analyze data from sensors within the furnace, providing insights into performance metrics such as temperature profiles, heating patterns, energy consumption, and maintenance needs. This data-driven approach facilitates proactive maintenance and troubleshooting.

4. Data Acquisition & Analysis :

- Automated systems enhance safety by implementing protocols for emergency shutdowns, monitoring hazardous conditions, and ensuring compliance with safety regulations. Automated alarms and safety interlocks mitigate risks associated with high-temperature operations.

5. Safety and Compliance :

- Automation in industrial furnaces can be integrated with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. This integration facilitates seamless data exchange, production planning, and resource allocation across the manufacturing facility.

6. Integration with Manufacturing Systems :

- Emerging technologies such as artificial intelligence (AI) and machine learning (ML) are increasingly applied in automation for industrial furnaces. These technologies can predict furnace behaviour optimize operational parameters in real-time, and support predictive maintenance strategies.

Advanced Technologies:

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility

Why Creote

Affordable & Flexible

Must explain too you how all this mistaken idea of denouncing pleasures praising pain was born and we will give you complete account of the system the actual teachings of the great explorer.

- Cost-Effective Services

- Helps Reduce Business Risks

- Management of Employee Performance

- Increasing Company’s Agility